Research & Development and Quality Control

We design investment casting waxes besed on the unique needs of our customer. We considen the wax characteristics and properties that may be required,including viscosity, elastic modulus and contraction rates to the largest extent possible.

Initially our focus was on wax-blending.We were then the first to introduce a wax recycling process-not only for runners,but for pattern wax as well. Through ongoing research, testing, and development, we learned how to treat recycled wax in such a manner that it brought quality levels to that of virgin wax.

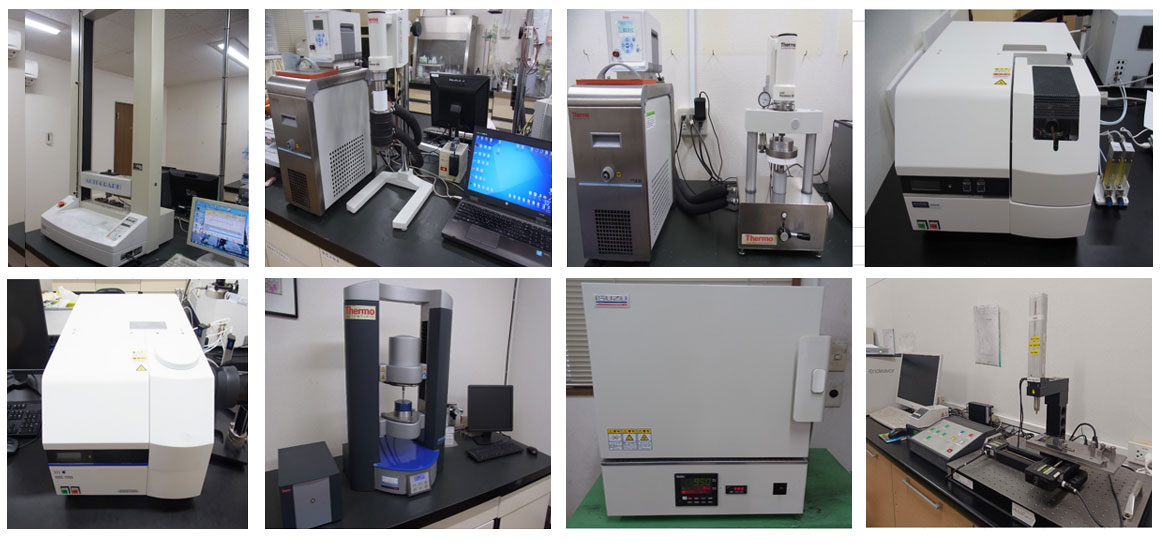

In our laboratory, we continue to develop wax-making technologies that create the best waxes in the market.Wax have established test machines that can analyze wax characteristics including expansion ratios and surface finish checks.We also utilize precise viscosity measurement instruments in our analysis.

Our database system allows us to design any pattern wax from virgin wax to reclaimed or reconstituted wax, based on the customer's requirements. We are capable of testing your current used waxs and are a ble to answer any question regarding that wax.

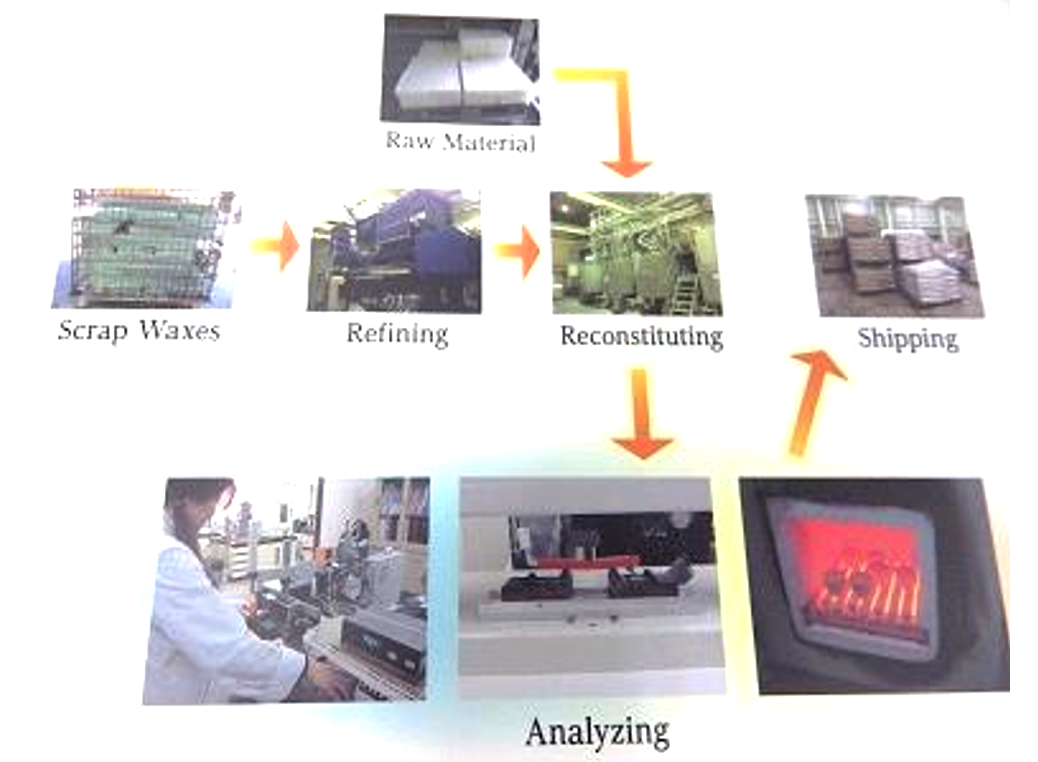

Reclaimed and Reconstituted Wax

Our mission at PCS is to offer our customers high quality waxs that perform at the highest and most cost-effetive levels. Our technonlogy allowss us to offer both reclaimed and reconstituted wax that will meet the specific needs of each customer.We are also capable of reclaiming and reconstituting most waxes that customers currently use as pattern waxes.

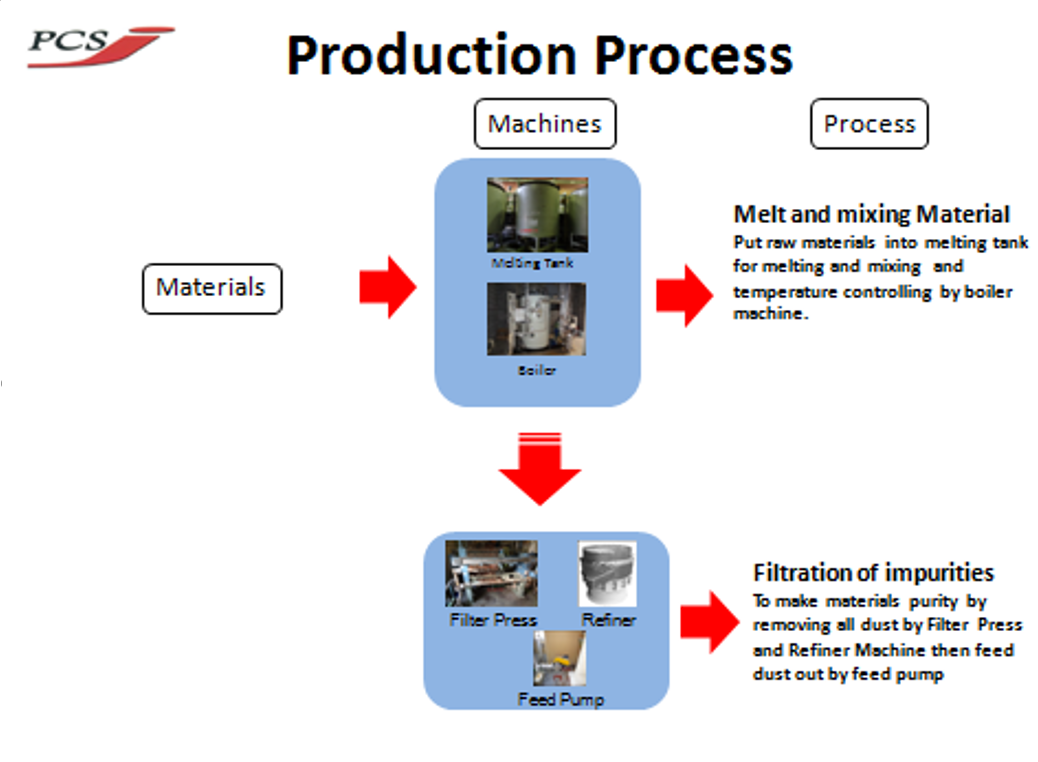

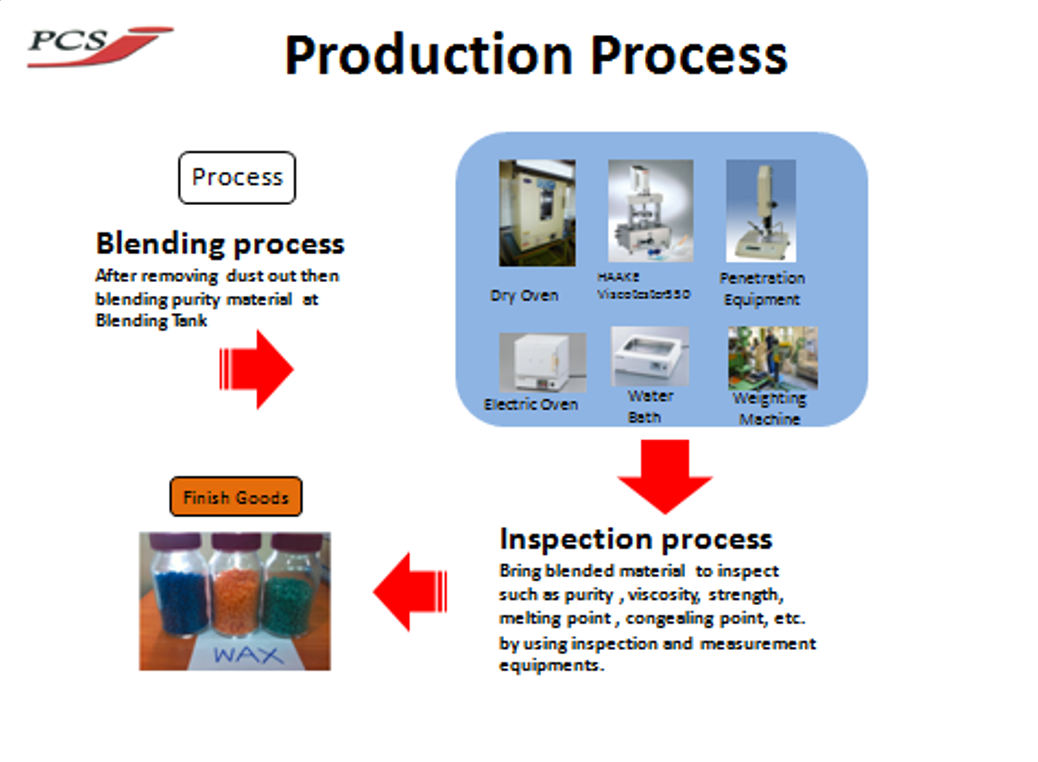

The Process

Customer send us their scrap waxes,such as steam autoclave waxes.These scraps are processed-water is removed and the wax is cleaned. Wax properties and characteristics are then evaluated and the data is captured in our database system.

Rew materials and ingredients are then incorporated into the cleaned wax based on the wax analysis performed. The wax properties are then tested again for viscosity ash content, and penetration to ensure they are near levels of virgin wax before they are returned to the customer. For those customers using reclaimed wax as runner wax, additional ingredients are introduced into the wax allowing them to achieve a lower melting point than pattern wax.